Aspect Biosystems CEO Tamer Mohamed, left, and chief technology officer Simon Beyer.DARRYL DYCK/The Globe and Mail

Imagine a procedure that could reverse the effects of Type 1 diabetes by implanting in patients living tissue produced by a 3-D printer that uses cells instead of ink or plastics. No more insulin shots. No daily blood tests.

It is the stuff of science fiction. Or it was.

Vancouver-based Aspect Biosystems is developing what’s called microfluidic 3-D bioprinting of human tissues to do just that. It’s currently in preclinical trial and the biotechnology company hopes to begin human clinical trials on the diabetes biotherapy within the upcoming years.

“What we’re doing is using our printing technology to create living tissue to replace damaged biological function inside of the body,” says Tamer Mohamed, the company’s co-founder and chief executive officer. “This is a frontier focus in terms of medical innovation, where we’re trying to turn sci-fi into reality and create living tissue that could really change patient care.”

The technology was developed at the University of British Columbia (UBC) in 2011, when Mr. Mohamed and his co-founders were researching ways to create advanced printing technology that would “print” biological structures.

The team was inspired by the Star Trek world, where a replicator instantly produces food and drink on demand.

“We watched the replicator growing up and this whole idea of actually being able to create a living thing out of nothing. I think we’re starting to see us turn that into reality,” Mr. Mohamed says. “If we could do that, the possibilities are limitless in terms of creating tissues to replace damaged tissues inside of the body. That was kind of the ‘a-ha moment’ and the inspiration because we think it could have a tremendous impact.”

A ‘Frankenstein moment’

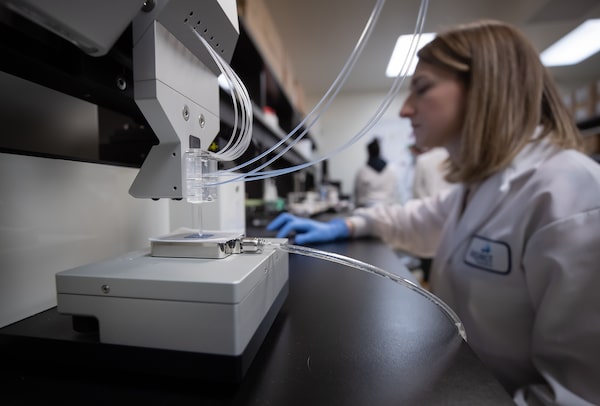

Erin Bedford, head of academic partnerships at Aspect Biosystems, uses a RX1 bioprinter to make a 3D tissue patch.DARRYL DYCK/The Globe and Mail

The first tissue the team printed while still at the UBC lab was a tubular tissue from airway smooth muscle, which is the muscle that wraps around the airway and is constricted in an asthma attack. To mimic such an attack, they added histamine, the compound that triggers the constriction.

While monitoring the process by video, they noticed the tissue start to constrict – a “Frankenstein moment” that drew everyone in to celebrate.

“That was probably the a-ha moment for me,” says Simon Beyer, co-founder and chief technology officer of Aspect Biosystems. “It suddenly became very, very real and a very, very reachable goal.”

In 2016, the innovation left the lab at UBC and Aspect Biosystems was founded. With backing from Toronto-based Radical Ventures, they have grown from 10 people to nearly 70. The company has more than 22 granted patents and 60 pending patent filings.

The company has raised over $50-million in Series A funding and has more than 30 partnerships around the world with both large pharmaceutical companies and academic researchers, involving everything from kidney to cardiac to neural tissue.

The Aspect Biosystems platform takes living cells, mixes them with various biomaterials and prints layer-by-layer to create living tissues. To create more widely applicable therapies, the company doesn’t use cells from the patient, but rather “off-the-shelf” donor cells or stem cells, and then uses biotechnology to “hide” the cells from the immune system to prevent rejection, Mr. Mohamed explains.

There are numerous potential applications, which posed a challenge for the creators in the early days: With so much need and so many possibilities, what to focus on?

In the end, to advance the technology as quickly as possible, Mr. Mohamed says the company decided to focus internally on two key areas; Type 1 diabetes and liver tissues to treat a variety of acute and chronic liver diseases. The collaborations with pharmaceutical companies and academics run the gamut of other applications.

The pancreatic tissue is currently in preclinical testing, meaning it is being evaluated on animals. Mr. Mohamed is hopeful that it will advance to clinical, or human, trials in the coming years.

“We’re printing the cells that those patients don’t have, the beta cells that actually sense glucose and release insulin,” he explains. “We’re printing those into a tissue that we implant so that those patients have a sort of a pancreatic tissue that actually senses glucose and releases insulin and will take them off of insulin injections.

“That’s currently in animal stages, where we’ve been able to demonstrate reversal of diabetes in small animals using our printed tissues.”

The liver tissues are also in development in preclinical testing.

Using machine learning to advance

The Aspect Biosystems platform takes living cells, mixes them with various biomaterials, and prints layer-by-layer to create living tissues.DARRYL DYCK/The Globe and Mail

The technology continues to evolve, thanks in part to machine learning, Mr. Beyer says.

Quality and repeatability are extremely important to this type of clinical manufacturing, he says. Aspect Biosystems uses extensive visual monitoring of their entire process, then relies on machine learning to pull out information from that monitoring to continually improve the quality of the platform.

Machine learning also allows the team to streamline the design process by tackling the complexity of the data involved. These biotherapeutics are widely hailed as the future of medicine.

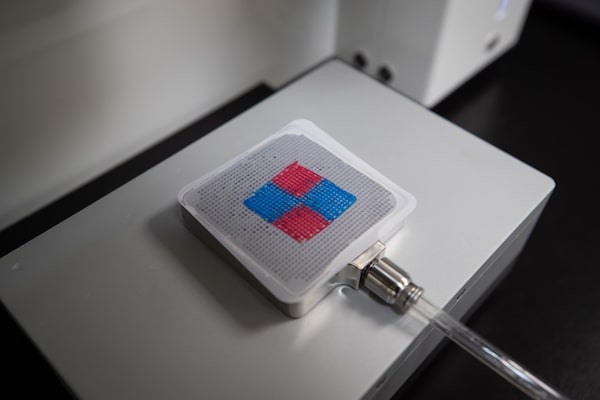

A 3D tissue patch after being made with a RX1 bioprinter.DARRYL DYCK/The Globe and Mail

Mr. Mohamed says the move from chemical-based drugs to biologics is a paradigm shift in the treatment of disease.

“A hundred years ago, drug development was basically done by chemists. Then several decades later, you started to have biotechs emerge that took a biological approach to drug development,” he says.

“Now we’re starting to see chemists working with biologists but also working with engineers. I think we’re going to see the next revolution. In 20 to 30 years, people are going to take for granted that we’re able to produce complicated organ systems and actually replace those into the body.”

Using AI to unlock the human cell science

There are an estimated 30 trillion to 40 trillion cells in the human body. It’s an estimate because, despite the astonishing advancements of science over the past century, we still have a relatively limited understanding of the complex organisms and interactions of the human body.

However, the rise of artificial intelligence (AI) and machine learning (ML) will have the same impact on biology today that electrification had on industry in the 19th century, says Konrad Walus, a co-founder and board director of Aspect Biosystems and professor in the UBC department of electrical and computer engineering.

“The advent of electricity completely changed industry. Electrification spread because it was clear that it was providing significant advantages and efficiencies for companies and it permeated and affected every machine, every technology that we use,” Dr. Walus says.

“I see AI and machine learning in the same way. Our biology in many ways is a perfect candidate for AI and ML, because we’re talking about a highly dimensional problem where humans really are limited in their capacity to kind of wrap their minds around all of the different angles and dimensions and parameters involved.”

The technology at the core of Aspect Biosystems was invented in Dr. Walus’s lab at UBC, where Mr. Mohamed and Mr. Beyer were graduate students. (The company’s fourth co-founder is chief scientific officer Sam Wadsworth.)

The UBC team and the company were recently awarded $148,000 in funding from the Innovate BC Ignite Program for a collaborative project to develop machine vision systems to help monitor and produce better tissues with the Aspect Biosystems 3-D bioprinting technology.

The process is very versatile but it has a lot of parameters, Dr. Walus says.

“One of the things that AI and ML systems are good at is reducing complexity and reducing dimensionality,” he adds. “With this project, we’re trying to apply machine vision and machine learning to the monitoring and control of the bioprinting system.”

Advancements from the project are now being integrated into the platform but it is just the first step in a bigger vision that can only be unlocked with AI, he says.

“This is a living system, so it’s one of the spaces where humans will always have a hard time really making major advances,” Dr. Walus says. “It’s only with AI and ML that we can reach sort of the next-next levels.”

The technologies can help extract the knowledge to accelerate the development of novel tissues and biotherapeutics, he says.

Over the next two to 10 years, he expects to see several lifesaving technologies coming out of this emerging field.

“The cell is infinitely complex. The more you look deeper, the more complex it gets,” he says. “So, we need help from technology like this to really accelerate and move to the next level.”